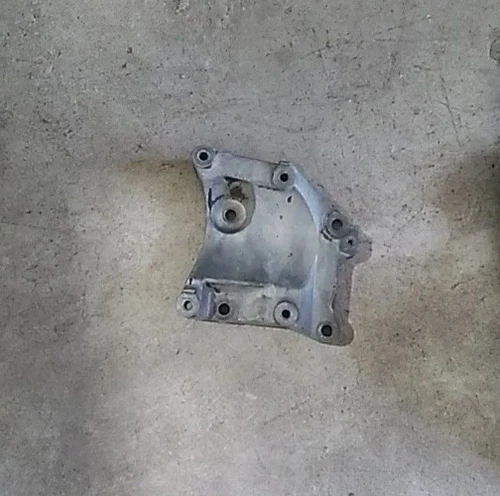

AC Compressor Bracket

AC Compressor Brackets: Precision Mounts for Lasting Cooling Power

Accessory-drive engineers treat the AC compressor bracket as a structural member, not just a slice of sheet metal. It locks the compressor housing to the block or timing cover, keeps pulley geometry square to the drive belt, and damps vibration so the AC clutch can engage smoothly even when the engine twists under load.

Most owners obsess over the AC compressor or refrigerant levels, yet the bracket quietly takes the hit from every clutch engagement. When mounting flanges corrode, dowel pins loosen, or bushings collapse, the compressor nose tilts by fractions of a degree. That tiny shift ripples through the belt path, overworks the belt tensioner, and shows up as squeal, premature bearing wear, or mystery leaks that keep returning after a new compressor install.

Treat the bracket like any other precision mount. Clean the mating surfaces, check flatness with a straightedge, and measure alignment with laser or string tools before bolting down the replacement AC compressor. If engine rocking from tired engine mounts or an improvised alternator bracket swap is stressing the mount, address those root causes. Upgraded brackets with reinforced ribs or steel inserts, paired with fresh hardware torqued in sequence, stop the vibration cycle and protect the expensive refrigerant charge you just paid to recover and refill.

Filters & Navigation

Showing 12 of 39 products

Deconstructing AC Compressor Bracket Reliability

Why Bracket Geometry Controls Cooling Output

Modern variable-displacement compressors cycle dozens of times in traffic, asking the bracket to absorb repeated torsional loads plus 150 to 220 pounds of belt tension. If its mounting pads lose parallelism to the crank pulley by even 0.2 degrees, compressor amperage climbs, cabin vent temps rise, and vibration travels through adjacent accessories. On transverse engines where the bracket bolts through the timing cover, a worn dowel sleeve can alter alignment enough to upset the belt tensioner calibration. That's why every OEM procedure pairs bracket inspection with a AC compressor replacement.

Failure Modes That Start at the Mounting Ears

Bracket damage rarely announces itself until after the new compressor fails. These are the patterns technicians document most often:

- Fretting and bolt-hole elongation: Micro-movement under load polishes the aluminum and lets bolts back out, creating black oxide dust around each fastener.

- Casting fractures: Stress risers near rib junctions crack when turbo engines add heat to the accessory drive, especially on brackets with thin webs.

- Galvanic corrosion: Road salt and dissimilar metals eat away at the mating surface until the compressor sits crooked and the belt tracks off-center.

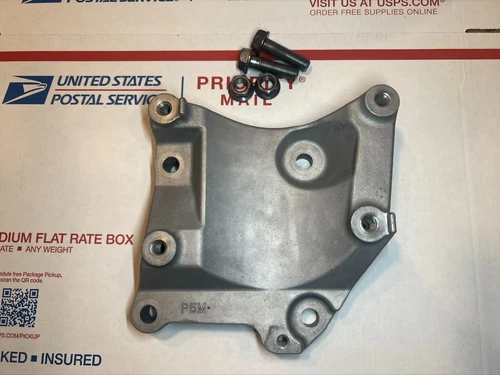

Inspection Blueprint Before You Reinstall

Use a metered process before hanging the new bracket or reusing an old one:

- Lay a machinist straightedge across the mounting pads and reject any bracket showing more than 0.004 inch of daylight.

- Use a belt laser or string alignment tool to compare pulley faces; anything beyond 1 mm offset across the compressor clutch warrants correction.

- Chase every threaded hole, replace stretch bolts, and torque in a crisscross pattern to avoid twisting the bracket during installation.

- Document shim stack or spacer locations so accessory stacking order matches OEM alignment.

When to Replace Versus Recondition

Aftermarket and OE suppliers now offer reinforced castings and billet options, but you still need a decision matrix:

- Replace any bracket with visible cracks, warping, or oxide trails because welding or grinding changes heat treatment and voids warranty.

- Recondition only clean castings by media-blasting, checking for porosity, and finishing with anti-corrosion coating before reinstall.

- Upgrade to kits that include dowel sleeves and hardware when swapping platforms, especially if the bracket also supports the alternator bracket.

- Pair the new bracket with inspections of engine mounts bushings so drivetrain movement doesn't undo your work in a few months.