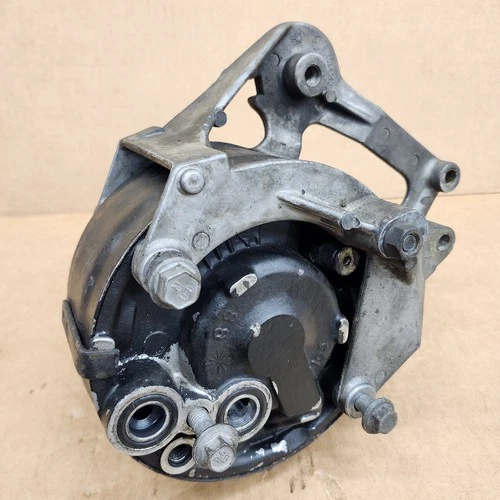

AC Compressor

AC Compressors: The High-Pressure Core of Every HVAC System

Every degree of cooled air inside the cabin starts with the AC compressor squeezing refrigerant vapor to pressures that can exceed 275 PSI. That mechanical pump is the only component that turns rotary engine power into the pressure differential that drives the entire AC cycle, so its health determines whether you get frosty vents or sticky heat.

Drivers tend to add refrigerant or blame the AC condenser when vents go warm, yet more than half of comeback repairs logged by dealership service managers stem from compressor inefficiencies. A weak clutch, slipping belt, or dragging AC compressor bracket mount wipes out pressure before it reaches the expansion valve, and the rest of the system never catches up.

Professional shops chase numbers before swapping parts: measure suction/discharge pressure, compare subcooling across the AC condenser, command the AC condenser fan, and scope the clutch amperage. Once you confirm the compressor is the bottleneck, match the exact mounting ears, control-valve style, and refrigerant spec, then flush or replace contaminated components so the new unit isn't doomed by old debris.

Filters & Navigation

Showing 12 of 49 products

Controlling the Physics Behind AC Compressor Reliability

Pressure Targets That Define Performance

A healthy system will show low-side pressures around 30–35 PSI with a high-side that tracks 2.2–2.5 times ambient temperature. Deviations tell you where to hunt: high suction/low discharge points to leaking reed valves, while low suction/high discharge usually indicates a starved AC condenser or airflow failure that overheats the compressor oil.

Failure Patterns Techs See Every Day

Watch for these silent warning signs before the compressor grenades:

- Dark, syrupy oil around the front seal signals clutch drag or bracket misalignment that cooks the seal.

- Glitter in the receiver-drier or orifice tube reveals internal wear—flush isn't enough, plan full component replacement.

- Repeat belt squeal after replacements almost always means the AC compressor bracket or belt tensioner is out of spec.

- Rapid cycling under light load suggests the control valve is sticking due to contaminated oil or electrical issues.

Diagnostic Workflow Before You Condemn the Compressor

A disciplined checklist saves hours of guesswork:

- Verify refrigerant weight with a recovery machine; overcharging mimics compressor failure.

- Use scan data to watch commanded vs. actual displacement or clutch duty cycle.

- Command the AC condenser fan and inspect for voltage drop—airflow issues overheat the compressor oil and spike head pressure.

- Inspect the AC compressor bracket and mounting bushings for movement; a 1 mm misalignment will overload the clutch bearing.

Replacement Strategy That Protects the New Compressor

Follow OEM-level steps so the next unit lasts:

- Replace the AC condenser or install an OE-approved parallel-flow service unit after any catastrophic failure—flushing won't clear micro-channels.

- Swap the receiver-drier, metering device, and O-rings to keep moisture out of the oil.

- Pre-measure oil quantity and balance it across the condenser, evaporator, and compressor according to OEM spec.

- Pull a 29 inHg vacuum for at least 30 minutes, then weigh in the exact refrigerant charge before leak-checking.