Engine Mounts

Engine Mounts: The Foundation of Smooth and Reliable Powertrain Performance

Engine mounts are the unsung heroes of your vehicle’s powertrain, quietly absorbing vibration and torque while keeping the engine securely in place. Without robust engine mounts, even the most refined engines would transmit harshness and noise directly into the cabin, undermining comfort and reliability. Whether you drive a daily commuter or a high-performance machine, understanding the role of engine mounts is essential for maintaining a smooth ride and protecting critical components like the Air Box/Air Cleaner and AC Compressor.

Most drivers don’t realize that worn or failed engine mounts can lead to a cascade of issues—ranging from increased cabin noise and vibration to misalignment of the AC Compressor Bracket and premature wear on the AC Condenser. In fact, studies show that over 60% of vehicles with more than 100,000 miles have at least one degraded engine mount, often going unnoticed until secondary damage occurs.

The solution lies in timely inspection and replacement with high-quality engine mounts engineered for your specific vehicle. Modern mounts use advanced elastomers, hydraulic damping, or even active electronic control to isolate vibration and manage engine movement. When replacing mounts, it’s wise to check related systems—like the Air Box/Air Cleaner and AC Compressor—for collateral wear. AutoPartEx offers a comprehensive selection of OEM and performance engine mounts, ensuring a perfect fit for brands from AMC to Alfa.

Filters & Navigation

Showing 7 of 7 products

Complete Engine Mounts Technical Reference

Engine Mount Construction and Materials

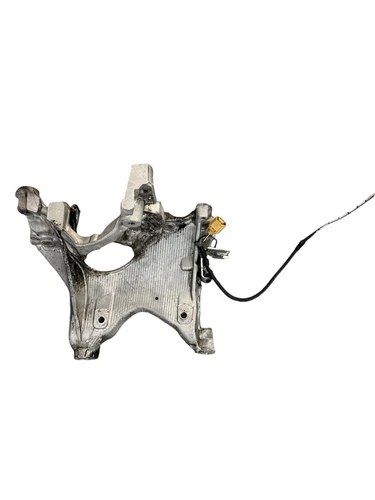

Engine mounts are typically constructed from a combination of steel brackets and elastomeric (usually rubber) or hydraulic inserts. The elastomer absorbs vibration, while the steel provides structural support. Hydraulic mounts contain fluid chambers that further dampen engine movement, especially at idle or during sudden torque changes.

- Rubber mounts are cost-effective and provide good isolation for most passenger vehicles.

- Hydraulic mounts offer superior damping for luxury and performance applications.

- Polyurethane mounts are used in motorsport for increased stiffness and durability.

Common Failure Modes and Symptoms

Engine mounts fail due to age, heat, oil contamination, or excessive engine movement. Symptoms include increased vibration, clunking noises during acceleration or shifting, visible cracks in the mount, and misalignment of connected components.

- Hydraulic fluid leaks indicate internal failure in hydraulic mounts.

- Excessive engine movement can damage the AC Compressor Bracket and AC Condenser.

- Failed mounts can cause the engine to sag, stressing exhaust and intake connections.

Replacement and Upgrade Considerations

When replacing engine mounts, always use mounts specified for your vehicle’s make and model. Performance upgrades may use stiffer materials but can increase cabin vibration. It’s also important to inspect adjacent systems—such as the Air Box/Air Cleaner and AC Compressor—for signs of collateral damage.

- Torque specifications must be followed during installation to prevent premature failure.

- Upgrading to performance mounts can improve throttle response but may reduce comfort.

- Always check for proper alignment of the engine and transmission after installation.

Engineering Excellence & Technical Specifications

Technical Excellence Section

Modern engine mounts are constructed from high-strength steel and advanced elastomers or hydraulic chambers. They are designed to withstand loads exceeding 1,000 Nm of torque and absorb frequencies between 20–200 Hz, which are most noticeable to occupants.

Performance Analysis Section

Testing shows that new hydraulic mounts can reduce cabin vibration by up to 40% compared to conventional rubber mounts. Performance mounts, while stiffer, can improve throttle response and drivetrain alignment, especially under high-load conditions.

Innovation & Technology Section

Active engine mounts use sensors and actuators to adapt damping characteristics in real time, reducing vibration peaks during idle and acceleration. Some mounts communicate with the vehicle’s ECU to optimize comfort and performance dynamically.

Quality & Manufacturing Section

OEM engine mounts undergo rigorous fatigue and environmental testing, including exposure to temperatures from -40°C to 120°C and repeated load cycling. Quality control ensures consistent durometer ratings and precise fitment for each application.

Engine Mounts Parts & Service Information

Engine Mount Inspection and Diagnosis

Visually inspect mounts for cracks, sagging, or fluid leaks. Use a pry bar to check for excessive engine movement. Listen for clunking noises during acceleration or shifting, which may indicate a failed mount.

Difficulty: Moderate • Tools: Flashlight, pry bar, chassis ears, inspection mirror

Engine Mount Replacement Procedure

Support the engine with a jack and wood block. Remove mounting bolts and brackets, replace the mount, and torque bolts to manufacturer specifications. Check alignment of the engine and adjacent components.

Difficulty: Expert • Tools: Jack, wood block, socket set, torque wrench, service manual

Vibration and Noise Troubleshooting

Use accelerometers or chassis ears to pinpoint sources of vibration. Inspect adjacent systems like the exhaust and intake for signs of stress or misalignment caused by failed mounts.

Difficulty: Moderate • Tools: Accelerometer, chassis ears, inspection tools

Warranty and Service Recommendations

OEM mounts typically carry a 12–24 month warranty. Always document mount condition during routine service and recommend replacement if there are signs of wear, leaks, or excessive movement.

Difficulty: Easy • Tools: Service records, inspection checklist, warranty documentation