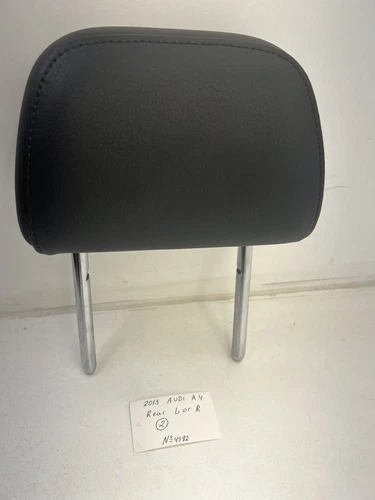

Headrest

Automotive Headrest Systems: Safety, Comfort, and Engineering Insights

Headrests are more than just a comfort feature—they are a critical safety component engineered to protect occupants from whiplash and spinal injuries during collisions. While often overlooked, the design and condition of your vehicle's headrest can significantly impact both comfort and crash safety. Understanding the technical and ergonomic aspects of headrests is essential for drivers, passengers, and fleet managers alike.

Most drivers and passengers underestimate the importance of a properly adjusted headrest. According to NHTSA, over 50% of whiplash injuries could be mitigated with correct headrest positioning, yet surveys show less than 30% of occupants set their headrests optimally. Many are unaware that headrests are engineered with specific energy-absorbing materials and mechanisms, and that worn or mismatched replacements can compromise safety. Even subtle differences in headrest geometry—such as tilt angle or height—can affect the effectiveness of the entire seat system, just as an incorrect Air Box/Air Cleaner can impact engine performance.

Smart solutions start with understanding the compatibility and specifications of your vehicle's headrest system. Always verify part numbers and material specifications, especially when sourcing replacements from platforms like AutoPartEx. Use OEM or certified aftermarket headrests to ensure compliance with safety standards. For vehicles equipped with active headrest or integrated electronics, consult your service manual and consider professional installation. Explore related components such as seat frames, seatbelt pre-tensioners, and even climate-controlled seating systems, which may interface with the headrest assembly. For more on seat system integration, see AC Compressor and AC Compressor Bracket.

Filters & Navigation

Complete Headrest Technical Reference

Headrest Safety Engineering and Crash Dynamics

Headrests are engineered to limit the relative motion of the head and torso during rear-end collisions. The optimal distance between the back of the head and the headrest is less than 2 inches (50 mm), and the top of the headrest should align with the top of the occupant's head. Energy-absorbing foams, steel inserts, and active mechanisms are tested to withstand forces exceeding 1,000 N during crash simulations. Headrest geometry is validated using anthropomorphic test devices (ATDs) to ensure compliance with FMVSS 202a and Euro NCAP standards.

- Active headrests deploy within 50 milliseconds of impact to reduce whiplash risk.

- Energy-absorbing foams are selected based on density and compression set resistance.

- Steel or composite inserts provide structural integrity and anchor points for seat-mounted airbags.

Material Selection and Comfort Optimization

Modern headrests use multi-layered foams, advanced textiles, and sometimes leather or synthetic coverings. The selection of materials affects not only comfort but also durability and safety. Temperature stability, UV resistance, and flame retardancy are key considerations. Some headrests incorporate ventilation channels or heating elements, requiring careful integration with seat electronics.

- Foam density typically ranges from 30 to 60 kg/m³ for optimal support.

- Cover materials are tested for abrasion resistance (Martindale > 20,000 cycles).

- Integrated electronics must meet ISO 16750-2 standards for automotive environments.

Integration with Seat Systems and Vehicle Electronics

Headrests are increasingly integrated with seat-mounted speakers, climate control, and active safety systems. Wiring harnesses and connectors must be robust against vibration and temperature cycling. Calibration of active headrest mechanisms is performed using diagnostic tools, and compatibility with seat airbag modules is essential for occupant safety.

- Wiring harnesses are rated for -40°C to +85°C operation.

- Active headrest actuators are tested for 100,000 deployment cycles.

- Seatback sensors and headrest modules communicate via CAN bus in advanced vehicles.

Engineering Excellence & Technical Specifications

Technical Excellence Section

Our headrests are sourced from OEM and certified aftermarket suppliers, with each unit tested for crash energy absorption, material durability, and ergonomic support. Specifications include foam density (30–60 kg/m³), steel insert thickness (1.2–2.0 mm), and compliance with FMVSS 202a.

Performance Analysis Section

Headrests undergo dynamic crash testing, with active systems deploying in under 50 ms and reducing whiplash forces by up to 40%. Material fatigue is evaluated over 100,000 adjustment cycles, and comfort is validated through pressure mapping and user trials.

Innovation & Technology Section

Advanced headrests feature integrated speakers, heating/cooling channels, and active deployment mechanisms. CAN bus compatibility and EMI shielding ensure reliable operation in electronically complex vehicles.

Quality & Manufacturing Section

Manufacturing partners adhere to ISO/TS 16949 and IATF 16949 standards, with rigorous quality control for foam consistency, cover material integrity, and electronic module reliability. Each batch is traceable for warranty and recall management.

Headrest Parts & Service Information

Headrest Adjustment and Installation

Ensure the headrest is installed securely by aligning the posts with the seatback guides and locking it in place. Adjust the height so the top is level with the top of your head and minimize the gap to less than 2 inches. For active headrest systems, follow the manufacturer's calibration procedure.

Difficulty: Easy • Tools: None or basic hand tools (if removal required)

Headrest Maintenance and Inspection

Inspect headrests for wear, damage, or loose fitment every 12 months. Clean with approved upholstery cleaners and avoid harsh chemicals that can degrade foam or coverings. For headrests with integrated electronics, check wiring and connectors for signs of wear.

Difficulty: Easy • Tools: Upholstery cleaner, inspection light

Headrest Diagnostic and Troubleshooting

For active or electronic headrests, use a diagnostic scan tool to check for fault codes after any collision or seat repair. Verify that all adjustment and deployment mechanisms operate smoothly and that wiring harnesses are intact.

Difficulty: Moderate • Tools: OBD-II scanner, multimeter

Headrest Service and Warranty Information

Refer to your vehicle's service manual for headrest replacement intervals and warranty coverage. OEM headrests typically carry a 12–36 month warranty. For recalls or safety notices, check with your manufacturer or AutoPartEx support.

Difficulty: Easy • Tools: Service manual, warranty documentation