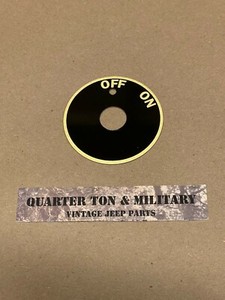

Ignition Switch

Ignition Switches: The Critical Link in Modern Vehicle Starting and Security

The ignition switch is more than just the place you turn your key—it's the gateway to your vehicle's entire electrical system. As the first point of contact between driver intent and engine response, the ignition switch coordinates power delivery to essential systems, from the starter motor to the fuel pump and advanced security modules. A failing ignition switch can leave you stranded, disable safety features, or even trigger immobilizer faults, making it a vital component for both reliability and security.

Most drivers don't realize that a worn or faulty ignition switch can mimic symptoms of a dead battery, failed starter, or even a malfunctioning Air Box/Air Cleaner. In fact, over 30% of 'no start' complaints are traced back to ignition switch issues rather than the starter or battery. Modern vehicles with electronic steering locks or push-button start systems rely on complex ignition switch assemblies that integrate anti-theft and immobilizer circuits. When these switches degrade, they can intermittently cut power to the AC Compressor, fuel injectors, or dashboard electronics, leading to unpredictable failures and costly misdiagnoses.

The solution lies in accurate diagnosis and sourcing high-quality, OEM-grade ignition switches. Technicians should use voltage drop testing and scan tool data to confirm switch integrity before replacing related components like the AC Compressor Bracket or AC Condenser. For vehicles with advanced security systems, pairing the new ignition switch with proper immobilizer programming is essential. AutoPartEx offers a curated selection of ignition switches, including rare and discontinued models for AMC, Acura, and Alfa vehicles, ensuring compatibility and long-term reliability.

Filters & Navigation

Showing 6 of 6 products

Complete Ignition Switch Technical Reference

Electrical Pathways and Contact Design

Ignition switches are engineered to handle multiple high-current circuits, including the starter solenoid, accessory power, and ignition coil feeds. Modern designs use silver-plated contacts for reduced resistance and improved longevity. Contact wear, pitting, or contamination can increase resistance by up to 50%, resulting in voltage drops that prevent reliable starting or accessory operation.

- Multi-position rotary or push-button actuation with distinct detents for accessory, run, and start modes.

- Integrated anti-theft circuits and immobilizer transponders in late-model vehicles.

- Contact material selection (copper, silver alloy) directly impacts switch lifespan and reliability.

Failure Modes and Diagnostic Strategies

Common failure modes include worn contacts, broken return springs, and internal short circuits. Diagnostic strategies involve measuring voltage at the output terminals during key cycling, checking for intermittent drops, and using scan tool data to monitor immobilizer status. In some cases, a faulty ignition switch can trigger false codes for unrelated modules, such as the AC Condenser Fan or airbag system.

- Intermittent no-start or accessory loss often traced to internal switch wear.

- Scan tool monitoring of ignition status and immobilizer handshake.

- Physical inspection for heat discoloration or melted connectors.

Integration with Security and Starting Systems

Modern ignition switches are deeply integrated with vehicle security, including immobilizer chips, steering column locks, and keyless entry modules. Replacement often requires reprogramming or synchronization with the vehicle's ECU. Failure to properly pair the new switch can result in persistent no-start conditions or security lockouts.

- Immobilizer chip pairing and ECU handshake required for most post-2000 vehicles.

- Steering lock integration adds mechanical and electronic complexity.

- Aftermarket switches must match OEM pinouts and security protocols.

Engineering Excellence & Technical Specifications

Technical Excellence Section

Our ignition switches are manufactured with silver-plated contacts, robust detent mechanisms, and high-durability return springs. Each unit is tested for contact resistance below 0.05 ohms and mechanical cycle life exceeding 100,000 operations.

Performance Analysis Section

Performance testing includes voltage drop analysis under full starter load, accessory circuit continuity, and immobilizer handshake verification. Comparative data shows OEM-grade switches maintain stable voltage within 0.2V of battery supply, while inferior units can drop over 1V under load.

Innovation & Technology Section

Modern ignition switches feature integrated immobilizer antennas, electronic steering lock modules, and support for push-button start systems. Our catalog includes programmable units for late-model vehicles and rare configurations for classic and specialty models.

Quality & Manufacturing Section

Each switch undergoes rigorous quality control, including thermal cycling, vibration testing, and connector integrity checks. Manufacturing partners are ISO/TS 16949 certified, ensuring consistent quality and compatibility across all vehicle platforms.

Ignition Switch Parts & Service Information

Ignition Switch Removal and Installation

Disconnect the battery, remove steering column covers, and unbolt the ignition switch. Carefully disconnect electrical connectors and note key position. Install the new switch, ensuring correct alignment and secure all fasteners. Reconnect the battery and test all key positions.

Difficulty: Moderate • Tools: Screwdrivers, socket set, trim removal tools, multimeter

Ignition Switch Maintenance

Inspect for signs of wear, heat discoloration, or loose connectors during routine service. Lubricate key cylinder (if applicable) with graphite, not oil. Check for smooth key operation and consistent accessory power delivery.

Difficulty: Easy • Tools: Graphite lubricant, inspection light

Ignition Switch Diagnostic Procedures

Use a multimeter to check voltage at each switch terminal during key cycling. Scan for immobilizer or security codes if equipped. Inspect connectors for corrosion or heat damage. Confirm continuity in all positions.

Difficulty: Expert • Tools: Multimeter, scan tool, wiring diagram

Ignition Switch Service and Warranty

Follow OEM procedures for replacement and programming. Document all steps and test for proper operation. Most switches carry a 12-24 month warranty when installed by a professional.

Difficulty: Moderate • Tools: Service manual, programming tool, warranty documentation