Fuel Tank

Fuel Tank Systems: Engineering, Maintenance, and Replacement Guide

The fuel tank is the unsung hero of your vehicle’s powertrain, quietly storing and delivering the energy that drives every journey. While most drivers rarely think about their fuel tank until a problem arises, this component is a complex blend of materials science, safety engineering, and emissions control. A compromised tank can lead to leaks, vapor loss, or even catastrophic failure, making its integrity critical for both performance and safety.

Many vehicle owners are unaware that even a small crack or corrosion spot in a fuel tank can result in a 10% drop in fuel efficiency and pose significant fire hazards. Modern tanks are engineered to withstand impacts, resist chemical degradation, and contain vapors, but age, road salt, and debris can silently erode these protections. Issues like fuel odors, hard starting, or check engine lights are often traced back to the tank or its related systems, not just the more visible Air Box/Air Cleaner or AC Compressor components.

Addressing fuel tank issues requires a holistic approach. Inspection should include checking for rust, swelling, or seepage, as well as testing the evaporative emissions system. Replacement tanks must meet OEM specifications for material, capacity, and emissions compliance. When replacing a tank, it's wise to inspect associated parts such as the Air Box/Air Cleaner, AC Compressor, and AC Condenser for wear or contamination. AutoPartEx offers a curated selection of OEM and high-quality aftermarket tanks, ensuring compatibility and safety for every application.

Filters & Navigation

Showing 6 of 6 products

Comprehensive Fuel Tank Technical Reference

Fuel Tank Materials and Construction

Modern fuel tanks are constructed from high-density polyethylene (HDPE), steel, or aluminum, each offering unique advantages. HDPE tanks are lightweight and corrosion-resistant, while steel tanks provide superior impact resistance. Internal baffles reduce fuel slosh, and multi-layer designs help contain vapors. Tanks must pass rigorous drop, puncture, and pressure tests to meet FMVSS 301 standards.

- HDPE tanks resist corrosion and are up to 30% lighter than steel equivalents.

- Steel tanks are often coated with zinc or epoxy for added protection.

- Multi-layer plastic tanks include vapor barriers to meet emissions regulations.

Fuel Tank Integration with Emissions and Delivery Systems

The fuel tank is central to the evaporative emissions system, working with components like the charcoal canister and purge valve. Pressure sensors and vent lines ensure that vapors are captured and routed to the engine for combustion. Any breach in the tank or its seals can trigger OBD-II codes such as P0440 or P0455.

- Integrated pressure sensors monitor tank integrity and vapor containment.

- Vapor lines must be checked for cracks or disconnections during service.

- Fuel pump modules are often housed within the tank, requiring careful handling during replacement.

Replacement and Service Considerations

Replacing a fuel tank involves draining fuel, disconnecting lines, and safely lowering the tank. All seals, straps, and sending units should be inspected and replaced as needed. Proper torque specifications must be followed to prevent leaks or sensor errors.

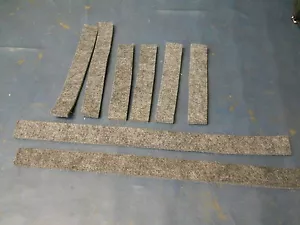

- Always replace tank straps and insulators to prevent future corrosion.

- Use OEM-approved sealants and gaskets for reassembly.

- Test the evaporative system for leaks after installation.

Engineering Excellence & Technical Specifications

Technical Excellence Section

Our fuel tanks are constructed from HDPE, steel, or aluminum, with multi-layer vapor barriers and internal baffles. Each tank is pressure-tested to withstand over 30 psi and meets FMVSS 301 crash standards.

Performance Analysis Section

We analyze tank performance using pressure decay tests, vapor containment metrics, and impact resistance data. Tanks are validated for compatibility with ethanol blends and modern emissions systems.

Innovation & Technology Section

AutoPartEx offers tanks with integrated sensor ports, modular pump assemblies, and advanced anti-corrosion coatings. Our selection includes direct-fit and universal options for classic and late-model vehicles.

Quality & Manufacturing Section

All tanks are sourced from certified manufacturers, with rigorous quality control for weld integrity, material thickness, and vapor barrier performance. Detailed fitment data ensures every tank matches OEM requirements.

Fuel Tank Parts & Service Information

Fuel Tank Inspection and Leak Detection

Visually inspect for rust, swelling, or seepage. Use a smoke machine to detect vapor leaks. Check all lines and seals for cracks or wear.

Difficulty: Moderate • Tools: Flashlight, smoke machine, inspection mirror

Fuel Tank Maintenance Schedule

Inspect the tank annually, especially in regions with heavy road salt. Clean the exterior and check for signs of corrosion or damage. Replace straps and insulators as needed.

Difficulty: Easy • Tools: Jack stands, cleaning brush, rust inhibitor

Fuel Tank Diagnostic Procedures

Diagnose check engine lights related to evaporative emissions (codes P0440, P0455). Use a scan tool and pressure tester to check for leaks or sensor faults.

Difficulty: Expert • Tools: OBD-II scan tool, pressure tester, multimeter

Fuel Tank Replacement and Service

Safely drain and remove the tank, replace all seals and straps, and torque fasteners to spec. Test the system for leaks after installation.

Difficulty: Expert • Tools: Transmission jack, socket set, torque wrench, new seals